Fall 2022

Engineering Around the Supply Chain

– Andy McMillan

This truck top camper company weathered supply chain challenges by making their own. Now, they are innovating to help other small businesses.

Graeme MacPherson is obsessed with continuity. As a cofounder and the face of Go Fast Campers–a direct-to-consumer, platform camper company–he’s learned to be that way. In the company’s short existence, it has weathered a global pandemic and the supply chain issues that followed. But it hasn’t been easy.

Based in Belgrade, Montana, about 20 minutes outside Bozeman, the small business installs approximately 40 campers, 6 rooftop tents, and 8 truck toppers each week. Outdoor enthusiasts make the pilgrimage to the company’s headquarters for the installation, often using vacation time and driving great distances to pick up a camper that will be assembled just in time for their arrival. While the company’s typical customer relishes the adventure of a trip to Montana, things can go wrong in a hurry.

Go Fast Campers announced itself in the fall of 2017 after a successful entrepreneur crowdfunding campaign, and almost immediately it faced production woes. “We completely underestimated how hard it would be to manufacture things in house,” MacPherson said over coffee in a Bozeman cafe. It had hoped to build two a week, with a largely US-based supply chain, but was only able to push out one every two weeks. “Some of our campers were delayed by 14 months.” For a company in its infancy, this was a major crisis.

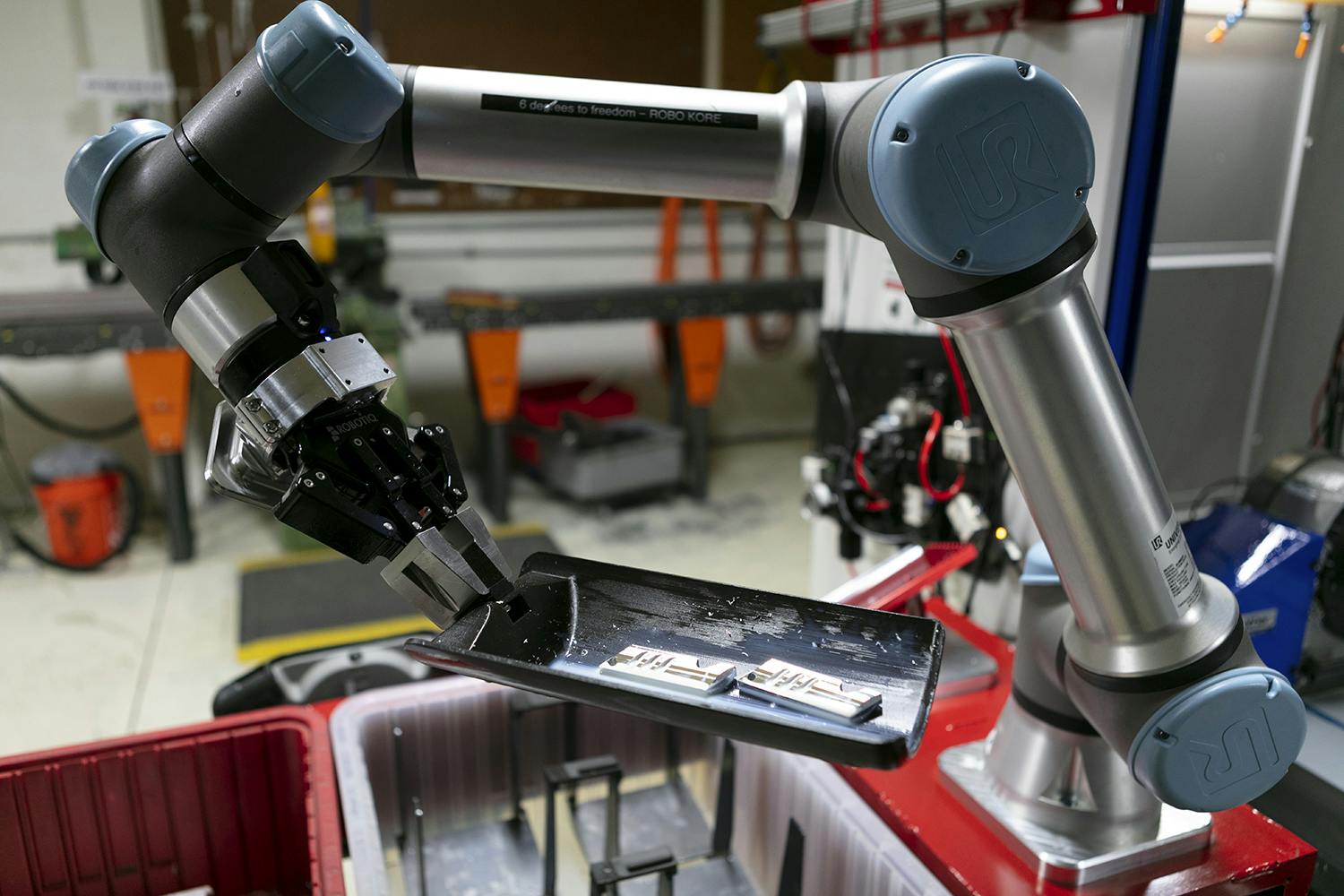

Another critical moment, McPherson recalls, was a delay getting the company’s first part sourced from China–a part that was integral to 2,000 campers that had already been sold. In the COVID-19 era, production delays are common; but the Go Fast Campers team was determined to develop its own domestic manufacturing system. Highly influenced by Toyota’s methodology, its approach embraces vertical integration; robotics capable of high-mix, low-volume machining; and engineering prowess to stay just in front of the growing demand for its product, despite the volatility of the supply chain.

To rectify this situation, MacPherson personally drove a trailer around the country making deliveries. After sleeping in the back of his truck to save money, he’d show up at customers’ doors, camper in tow and hat-in-hand, hoping to right a wrong that could have tanked the young company. If it were hot outside, he’d ask to use their shower before heading to the next delivery. On one trip, MacPherson and his wife, who was seven and a half months pregnant at the time, drove to upstate New York, down to Cocoa Beach, Florida, and then to Denver before returning to Bozeman. It was quite the apology tour.

“We knew we had to do everything ourselves so we could scale long term. The vision wasn’t just to make a camper company but to make a badass manufacturing company,” said MacPherson.

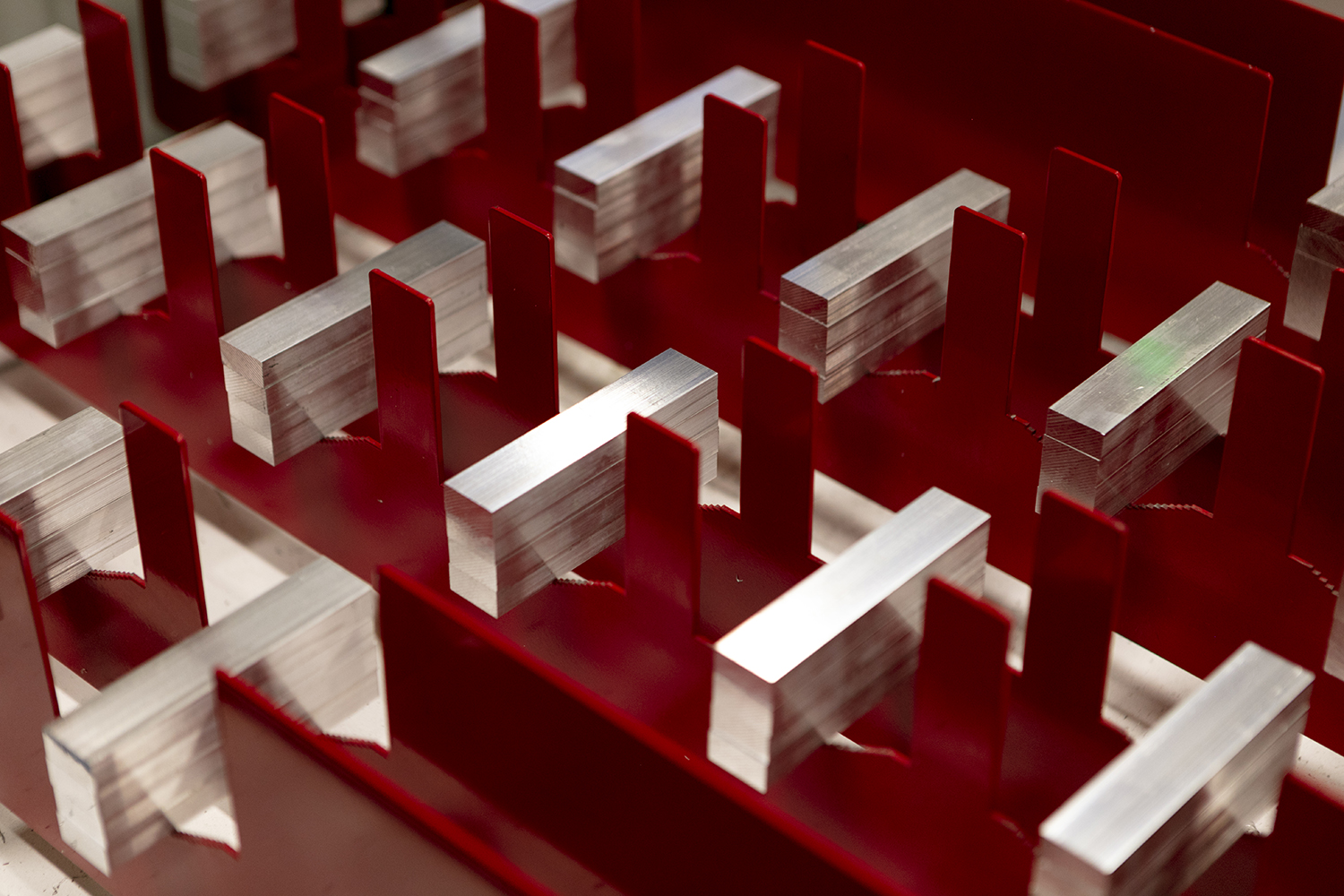

More than 800 components sourced from 190 different suppliers go into each Go Fast Campers camper. It manufactures everything it can in house, and it stocks the smallest quantity it can keep on hand while still fulfilling orders. This enables it to keep production in the raw materials phase as long as possible. If all of a sudden a part is unavailable, it turns to its engineering team.

“The easiest way around the supply chain is to change the product. We engineer our way out of it,” MacPherson said. By doing so, the company is able to keep the production process from grinding to a halt with each shortage. And since it produces relatively small numbers of parts at a time, is isn’t left with the financial burden of having stockpiles of obsolete parts.

With 25% of its employees working in an engineering capacity, Go Fast Campers aims to make a product that is built-for-life at a competitive price point. It is passionate about American-made products, but don’t expect consumers to veer from their budgets for the sake of ideology. “People can’t afford to care,” MacPherson said. “You have to make it economically viable.” And Go Fast Campers hopes to help other small businesses do the same.

That’s where Maschinen comes in. A start-up born from the company’s Special Projects Division, Maschinen will package innovation tools for small businesses, allowing others to benefit from the progress made by its engineering staff.

“Any tool we can build versus buy, we build, because nobody makes tools for small businesses,” MacPherson said. “Our competitive advantage is our innovative CNC [computerized numerical control] machining. Maschinen’s goal is to bring that same advantage to other small businesses, so they can be as competitive as we are.”

+ + + + +

Andy McMillan is a writer, filmmaker, and photographer living in Charlotte. His work has appeared in CNN, Time, the New York Times Magazine, and Vanity Fair, among others. He’s currently finishing his first feature documentary about a terminally ill cancer patient who chooses to spend his last days floating on the Mississippi River in a ramshackle houseboat.

Cover photo: A demonstration is run on the advanced computer numerical control—or CNC— machine that will be used for the company's new start up Maschinen, in Go Fast Camper's Special Projects unit. Manhattan, MT. September 16, 2022. Photos by Andy McMillan for Wilson Quarterly.